MASKE: A kinetic simulator of coupled chemical and mechanical processes driving microstructural evolution

Abstract

The microstructure of materials evolves through chemical reactions and mechanical stress, often strongly coupled in phenomena such as pressure solution or crystallization pressure. This article presents MASKE: a simulator to address the challenge of modelling coupled chemo-mechanical processes in microstructures. MASKE represents solid phases as agglomerations of particles whose off-lattice displacements generate mechanical stress through interaction potentials. Particle precipitation and dissolution are sampled using Kinetic Monte Carlo, with original reaction rate equations derived from Transition State Theory and featuring contributions from mechanical interactions. Molecules in solution around the solid are modelled implicitly, through concentrations that change during microstructural evolution and define the saturation indexes for user-defined chemical reactions. The structure and implementation of the software are explained first. Then, two examples on a nanocrystal of calcium hydroxide address its chemical equilibrium and its mechanical response under a range of imposed strain rates, involving stress-driven dissolution and recrystallization. These examples highlight MASKE’s distinctive ability to simulate strongly coupled chemo-mechanical processes. MASKE is available, open-source, on GitHub.

keywords:

A. chemo-mechanical processes , C. numerical algorithms , A. microstructures , Kinetic Monte Carlo.organization=Department of Civil and Environmental Engineering, Politecnico di Milano,addressline=Piazza Leonardo da Vinci 32, city=Milan, postcode=20133, state=MI, country=Italy

MASKE is presented: off-lattice Kinetic Monte Carlo on discretized microstructures

Original rate equations hard-coupling chemical reactions with mechanical stress

Dissolution/growth of a calcium hydroxide nanocrystal is simulated over long time

The crystal is put under realistic strain rates to compute stress-strain curves

A complex balance between solution chemistry, pressure solution, and plastic flow

1 Introduction

A strong coupling between mechanical stress and chemical reactions often underlies the microstructural evolution of materials. Examples of stress-driven nucleation and growth of materials are commonly found in nature, e.g. rock metamorphism or the adaptive growth of bones (Hart et al., 2017) and plants (Kouhen et al., 2023), but such processes are also exploited in nano-manufacturing, e.g. the heterogeneous precipitation of islands on top of mismatching crystals, which is a challenge in semiconductor production (Dubrovskii et al., 2010). Further examples concern the degradation of materials, such as crystallization pressure (Scherer, 2004), pressure solution (viz. pressure-induced dissolution, Rutter (1983)), creep from the relaxation of eigenstress originated during the formation of concrete (Bažant et al., 1997), and stress-corrosion cracking (Raja and Shoji, 2011).

In Solid Mechanics, the modelling of chemo-mechanical processes is quite established at the macroscopic continuum level, with fully coupled formulations of reactive transport and linear momentum conservation, e.g. in Gawin et al. (2009). At the constitutive level, these formulations sometimes consider the stress or strain stemming from phase transformations, e.g. local expansion during alkali-silica reaction and sulphate attack in concrete (Pesavento et al., 2012; Cefis and Comi, 2017), whereas the rates of chemical transformation are rarely stress-dependent (Bellomo et al., 2012). Chemo-mechanical modelling is less advanced at the smaller microstructural level, where the focus in on the evolving morphology of single, or multiple, crystalline and amorphous phases. The length and time scales of such microstructural processes are too large for direct atomistic simulations, hence appropriate coarse-graining approaches are needed. However, most current simulations of microstructural evolution either describe the geometry of growing/dissolving solids without addressing their stress field, or they focus on the mechanical interactions prompting structural aggregation and collapse, but considering chemical reactions only qualitatively. Among the former, with focus on chemistry, there are microstructural development codes such as in Van Breugel (1995); Bishnoi and Scrivener (2009); Bullard et al. (2011), as well as others simulators based on cellular automata (Bentz et al., 1994; Bullard et al., 2010) or on Kinetic Monte Carlo (KMC) (Martin et al., 2020). Examples of simulators with a focus on mechanics are instead those in Ioannidou et al. (2014, 2016, 2022), based on interacting particles. Exceptions exist, but with limitations. For example, (Li et al., 2015) and (Feng et al., 2017) staggered finite element simulations of mechanical response with a reactive module to simulate solid precipitation, respectively of stress-free cement hydrates during creep and of expanding ettringite during sulphate attack in a cement paste. In both cases, however, chemo-mechanical coupling was not intrinsic to the model, but imposed by alternating chemical and mechanical modules. Differently, Meakin and Rosso (2008) employed stress-dependent reaction rates in KMC simulations of crystal dissolution near stress-inducing dislocations. However the solid in these simulations was bound to a fixed lattice geometry (a cubic Kossel crystal), hence the stress field near the dislocation was pre-imposed and non-relaxing during dissolution. Another noteworthy method is the Phase Field, which does offer a framework to fully couple chemistry and mechanics; however, its high computational cost is preventing application to complex 3D structures, with multiple phases, liquid and solid, undergoing nonlinear mechanical processes (Tourret et al., 2022).

This work presents MASKE: a simulator of fluid-solid microstructures discretized via mechanically interacting particles whose dissolution and precipitation are sampled using off-lattice Kinetic Monte Carlo. MASKE allows the user to define multiple chemical reactions, along with their usual thermodynamic and kinetic parameters such as equilibrium constants and activation energies. Chemo-mechanical coupling is introduced through rate equations for the chemical reactions that feature the change in mechanical interaction energy accompanying particle dissolution or precipitation. Precursors of these rate equations where used in previous works. Shvab et al. (2017) captured the experimental hydration rate curve of a cement paste by simulating the nucleation and stress-driven agglomeration of calcium-silicate-hydrate nanoparticles. Coopamootoo and Masoero (2020) simulated the experimentally measured critical undersaturation of a tricalcim silicate (C3S) paste, below which stress-driven stepwave dissolution is initiated at screw dislocations; recently, Coopamootoo K (2023) have extended the result to finite-sized crystal, capturing the full experimental relationship between dissolution rate and saturation index of C3S. Alex et al. (2023) applied the coupled rate equations to the carbonation of a model cement paste, featuring multiple solid phases, ions in solution, and chemical reactions. These microscale simulations provided apparent rate constants that, employed in macroscale simulations of carbonation, matched a range of experimental results (Freeman et al., 2019). All these applications showed that the coupled reaction rates in MASKE can capture chemo-mechanical processes at experimentally realistic length and time scales. However, a detailed presentation and discussion of the architecture, capabilities, and limitations of MASKE are still due.

The algorithm and software architecture of MASKE are described in detail, accompanying its recent release, open-source, on GitHub (Masoero, 2023a). The main article focuses on the most important parts, concept,s and steps in the algorithm; much more details are provided in several appendices, which guide the interested reader to a deeper understanding of the method, while also describing the input, output, and some data structures of the software. In the main article, particular attention is paid to: (i) the stress-dependent rates of chemical reaction implemented in MASKE, and their relationship with Transition State Theory (TST) and its predictions; (ii) the KMC algorithm to sample particle dissolution and off-lattice precipitation; (iii) the possibility to integrate continuous kinetic processes in time along with discrete KMC events. These key features are demonstrated via two sample applications, both considering a spheroidal nano-crystal of calcium hydroxide Ca(OH)2 in an aqueous solution of its ions. The chemical kinetics of Ca(OH)2 under mechanical stress is of practical importance, as the instability and dissolution of this phase is responsible for pH drop and steel corrosion in reinforced concrete, and contribute to carbonation creep in cement pastes (Parrott, 1975). Here however the focus is not on experimental validation, which has been already addressed in part by the applications summarised in the previous paragraph. Instead, the aim here is to showcase the three key features of MASKE listed above. Hence, the first application considers the chemical equilibrium, dissolution, and growth of the Ca(OH)2 crystal in stress-free conditions; the results are compared with expectations from classical TST, and clarify the effect of some parameters in the rate equations and in the off-lattice sampling of precipitation. The second example puts the crystal under compression for a wide range of imposed strain rates; the results show that the interplay between mechanical deformations and stress-driven dissolution and recrystallization trigger rich and sometimes counter-intuitive mechanical responses, which are nevertheless explained by analysing the evolution of local stresses during the tests.

2 Methodology

This section presents for the first time the main structure and salient features of MASKE: a C++, object-oriented, parallel software that combines continuous processes, which are explicitly integrated in time, with discrete events, such as dissolution/precipitation reactions, sampled using off-lattice Kinetic Monte Carlo (KMC). In the Appendices, the interested reader can find full details of the MASKE algorithm, its implementation, the commands in its input script, and the parameters in its chemical database input file. In this section, attention is also paid to mechanical interactions between particles that are later used in two sample applications on Ca(OH)2 nanocrystals. The methodological details of these applications are provided here too.

2.1 Model description

A typical simulation features spherical particles in a prismatic simulation box with volume and periodic or fixed boundary conditions: see Fig. 1. Box and particles are generated and tracked using the LAMMPS C++ library interface (Thompson et al., 2022). The particles may represent any explicit phase, hereafter assumed to be solid ones. The particles interact mechanically with each other through user-defined interaction potentials, which are also defined and managed in LAMMPS: e.g. the interaction in Fig. 1. The current version of MASKE can only manage pairwise interactions, but extensions to any of the potentials in LAMMPS would be quite straightforward: see A for more discussion on this. Particle displacements caused by the mechanical interactions are also computed in LAMMPS, via usual methods such as molecular dynamics or energy minimization (respectively using the and commands in LAMMPS). This interface with LAMMPS gives the user flexibility to study complex systems with various mechanical interaction potentials and loading conditions.

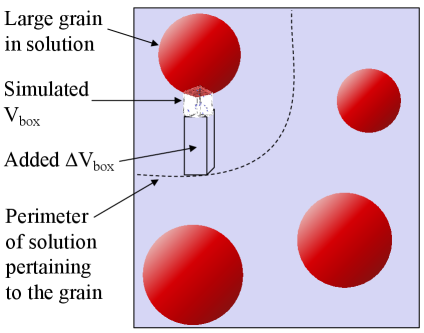

The portion of a simulation box that is not occupied by solid particles contains a volume of empty space, and a volume of implicit solution made up of various, user-defined molecular species. The current version of MASKE assumes that the molar concentrations of the solvated species are uniform in , with no diffusion taking place. There is also an additional volume attached to the simulation box, which can receive some of the molecules released during dissolution reactions, or provide some of the molecules consumed during precipitation reactions. This can be used to keep limited, which is where time-consuming operations take place; for example, Fig. 2 depicts a scenario where this approach allows focussing on dissolution and precipitation near the surface of a large grain, while preserving realistic concentrations in solution and surface-to-volume ratio of suspended grains at a larger scale. The initial molar concentrations of all the solvated molecules in and in are provided by the user in the input script, along with fixing the temperature of the solution and the and solvent parameters to be used in Debye-Hückel calculations of activity coefficients.

MASKE simulates discrete events, which happen once every units of time (where varies during a simulation depending on mechanical interactions and solution composition), but also continuous processes that are numerically integrated over a user-specified time interval with time step (for the continuous process). In the current version of MASKE, the possible discrete events are full dissolution (called ) of any existing particle, or full precipitation (called ) of a new particle at any possible location in . The only continuous process implemented so far is called : it repeatedly executes a set of stored LAMMPS commands, specified by the user in the MASKE input script (see C for more details on the input/output structure of the code). A process will be used in an example here, to impose a constant strain rate. The occurrence of discrete events and continuous processes is staggered onto a unique time line, , which is advanced by whichever event or process has the shortest time of future occurrence, or . The details of how this unique time line is managed can be found in B. The occurrence of discrete events is sampled using Kinetic Monte Carlo (KMC), thus the list of all possible discrete events is associated with a unique , which is the future occurrence time of any one out of all the possible discrete events. If is smaller than of all the other continuous processes, i.e. if a discrete event is next in line to be executed, then one discrete event is picked out from the list of all the possible ones, with a probability that is proportional to its individual rate. This is the usual approach in KMC simulations; specifically, MASKE uses a rejection-free KMC algorithm that is time-dependent (Prados et al., 1997), to account for changes in solution composition or stress state that continuous processes may induce between two successive discrete events. The equations of time-dependent KMC are also presented and discussed in B.

In the KMC method, is obtained from the cumulative rate:

| (1) |

which is the sum of the individual rates of all possible particle deletions plus all particle nucleations at all possible locations in the simulation box. The expressions for are presented in the next section. is finite, whereas the number of possible locations for particle precipitation is infinite and, in principle, one should sample them all to use KMC. To treat this problem, MASKE asks the user to select a region within and to create a 3D lattice of trial particles of the desired type, viz. with desired chemical composition and interaction potentials. Each of these trial particles is then driven towards its closest local minimum of interaction energy with the other already-existing, so-called particles (no interactions between trial particles are considered, and the positions of the real particles are kept fixed while moving the trial ones). This energy minimization is performed using a bespoke algorithm, called , which the algorithm in LAMMPS except that each trial particles is independently relaxed. The fineness of the user-specified lattice determines the volume of the generic lattice cell. The energy minimum obtained for a trial particle is assumed to characterize all the particles that may nucleate anywhere else in . In this way, the cumulative rate of all the sampled nucleation events is effectively a numerical integral in the sampled region, with resolution . The most accurate result is obtained when , but in practice a small but finite is already sufficient to estimate the cumulative nucleation rate accurately. How small should be, it depends on the employed interaction potentials and on the morphology of the simulated microstructure. An assumption underling this approach is that the energy minima alone fully control the precipitation rate cumulated over the whole . In reality, thermal fluctuations would add contributions also from the locations surrounding the minima; future versions of MASKE may sample such fluctuations by relaxing the trial particles using molecular dynamics instead of energy minimization. F offers more discussion on interaction energy landscapes and their sampling for dissolution and precipitation events.

The flowchart in Fig. 3 depicts the algorithm for the kinetic simulations in MASKE. A brief description is given here, while more details can be found in E. The left side of the flowchart summarises the sampling of for all the discrete and continuous processes in a simulation. The shortest determines which type of process or event is to be executed next. If a continuous process is next, it is directly integrated numerically over its time period (user-specified in the input script). After that, the individual rates of the sampled discrete events are multiplied times and these products are stored in a per-particle array called , of size . The array is used in the next kinetic step for computing . If the next event to execute is instead a discrete one, the values are immediately updated, adding to each entry the product . The values are then used to select which discrete event to carry out specifically, out of all the possible ones. After executing a discrete event, the concentrations of the solvated molecules are updated accordingly, as discussed in the next section, and the values are reset to zero. Subsequently, irrespective of whether the executed process is continuous or discrete, MASKE restores the initial position of all trial particles and executes a third type of possible processes, called . Unlike continuous or discrete processes, whose occurrence is associated to a time line, processes of type are simply executed once every kinetic steps, where a step is one full loop in Fig. 3. is user-specified as an input, and presently MASKE implements only one type of process, called , which executes a set of LAMMPS command that the user can specify and store in the input script. A typical use of such an process is to execute a full energy minimization of the system with , i.e. after each execution of a continuous or discrete process.

The algorithm in Fig. 3 is well suited to parallelisation, since each discrete event (i.e. each of the particle deletions and particle nucleations) can be sampled independently. Furthermore, spatial domain decomposition can be exploited during energy minimization. To exploit this, MASKE features a two-level parallelisation. On the first level, the user can specify multiple groups of processors, called , and attribute the sampling of one or more processes to each subcommunicator (e.g. one subcommunicator samples particle deletion, another one samples nucleation). On the second level, each subcommunicator uses all its processors to run any invoked LAMMPS command, e.g. energy calculations and minimisation using domain decomposition. This article does not report on the scalability and efficiency of the parallelisation, which is amenable to optimisation in the current version of MASKE. However, previously published works have already exploited both levels of parallelisation to simulate hundreds of thousands particles (Coopamootoo and Masoero, 2020) and multiple types of solid particles, all sampled for deletion and nucleation (Alex et al., 2023).

2.2 Chemical reactions: rates and mechanisms

MASKE computes the rate of any discrete event, such as particle deletion or nucleation, based on two user-defined entities: a chemical reaction and a reaction mechanism, both specified in a chemical database text file, called , whose syntax is presented in D. The chemical reaction is assumed to be one-step and is defined primarily through its formula and stoichiometric coefficients, e.g. :

| (2) |

for the dissolution of a calcium hydroxide molecule. The stoichiometric coefficients are specified in the file. The molecules appearing in the reaction formulas are also user-defined in the file, along with a set of useful parameters. For the solvated molecule, these parameters are its apparent volume , hydrated radius , ionic charge , and the parameter for Debye-Hückel calculations of activity coefficients, discussed later. For solid molecular species, only linear sizes are required, which are used to compute their molecular volumes. gathers also the thermodynamic and kinetic parameters associated to each chemical reaction: standard free energy barriers , standard concentrations of activated complexes (in the sense of Transition State Theory, which will be used below to express rate equations), equilibrium constants , and interfacial energies . See D for more details on this quantities.

The file also contains the definition of reaction mechanisms, which are the sets of assumptions that MASKE makes when assembling single chemical reactions to delete or nucleate a full particle. Indeed, a particle may be a coarse-grained entity whose deletion or creation may entail more than just a single reaction, e.g. or reactions respectively to dissolve or nucleate a particle. Classical Nucleation Theory is an example of multiple individual reactions being assembled to express a reaction rate at the particle scale. In the current version of MASKE, the only implemented mechanism is called and it assumes that, irrespective of how big a particle is, its full deletion or nucleation only takes the time for one single-step chemical reaction to occur. This is exact if the volume of the generic particle equals the sum of the volumes of solid molecules dissolving or precipitating in one reaction. For bigger particles instead, the mechanism effectively assumes that the same chemical reaction takes places everywhere in at the same time. This is clearly unrealistic for particles beyond the nanometre or so, therefore in this article all the examples will feature particles whose entail . Hereafter this resolution is called ’unimolecular’, although in principle a single chemical reaction might also involve multiple solid molecules at once.

Whenever a particle is deleted or nucleated, a chemical reaction is carried out as part of an mechanisms. MASKE ensures mass conservation by consistently managing molecule exchanges between solid phases and solution, following the user-specified reaction formulas in . Chemical reactions may entail differences in volume between reactants and products; these are accommodated in the volume introduced in the previous section, which may thus be positive or negative. The current version of MASKE does not simulate chemical reactions taking place in the implicit solution, hence it does not minimize the free energy of the solution itself. An interface between MASKE and the thermodynamic simulator PHREEQC (Parkhurst, 1995) is currently being developed, to address this limitation.

The rate equations for the mechanis in MASKE are rooted in Transition State Theory (TST), but with an extension to account for excess enthalpy coming from the mechanical interactions between particles. This excess enthalpy term, originally proposed in Shvab et al. (2017), is essential for capturing the effect of local morphology and stress state on reaction rates. The rate equations for one-step dissolution and precipitation reactions are:

| (3) | ||||

| (4) |

Eqs. 3 and 4 will be hereafter called ’straight’ rate equations, as opposed to ’net’ rates defined later in this section. is the probability of an activated complex evolving into reaction products; MASKE makes the common assumption that (Lasaga, 2014). and are the Boltzmann and Planck constants, and is the temperature in degrees Kelvin. and are the standard concentrations of activated complexes for the dissolution and precipitation reactions, and are their activity coefficients, and and are their standard free energies of activation. and can be estimated experimentally, noting that the whole prefactors in Eqs. 3 and 4 defines the rate constant :

| (5) |

Eq. 5 implies that the arbitrary choice of must be compensated by the value of , so that a physical, univocally defined rate constant is preserved. The details of this compensation are discussed in F.

The term in Eqs. 3 and 4 is the tributary volume of the particle being sampled for deletion or nucleation, viz. the volume of the interaction energy basin, whose local energy minimum is where the sampled particle sits. The user of MASKE must specify in the file; for solid phases governed by short-range interactions, is typically in the range of one particle volume (see F for more discussion and examples of ). is the spatial dimensionality of or ; namely, if the reactions are per unit volume or, as typical for dissolution/precipitation, indicating reactions per unit surface. is the cell volume of the user-defined lattice of trial particles sampling candidate nucleation sites. When the KMC algorithm sums all the nucleartion rates for trial particles pertaining to the same interaction energy basin, the sum of all ’s equals (within the limits posed by the finite, and not infinitesimal, value of ). As a result, in Eqs. 3 equals the sum of all pertaining to the same interaction energy basin. This aspect is discussed in more detail in G.

The square brackets in Eqs. 3 and 4 quantify the excess enthalpy of a particle, resulting from two contributions: , which is the change in total interaction energy in the system caused by the particle deletion ( is the analogous term for a nucleation even), and, which is the solid-solution interfacial energy attributed to the sampled particle, and user-defined in the file. The term, which multiplies in the excess enthalpy, is the surface area of the sampled particle. and appear in the excess enthalpy because the mechanism may be used for particles whose deletion or nucleation entails multiple chemical reactions; for the unimolecular resolution in this article, . The user-defined parameter , with value between 0 and 0.5, specifies which fraction of excess enthalpy is still present in the system when the reaction is in its activated complex state. is the usual assumption in TST, but results in this article will show that may sometimes improve the efficiency of a simulation.

The last terms to be defined in the rate equations are and , which are the activity products of the reactants in the dissolution and precipitation reactions. If is the generic solvated reactant:

| (6) |

where is the concentration in solution of the molecular species , is its stoichiometric coefficient in the reaction, and is its activity coefficient. MASKE computes using the WATEQ Debye-Hückel formula (Truesdell and Jones, 1974):

| (7) |

is the charge of the species. and are solvent-specific constants (0.51 and 3.29 nm-1 for water). is the hydrated radius of the molecule in solution, and is a molecule-specific dimensionless constant; both these parameters are provided by the user in the file. is the ionic strength of the fluid, featuring solvated species:

| (8) |

When or are unknown, MASKE computes the activity coefficients using established simplified methods (Langmuir, 1997), detailed in F.

The straight rate expressions in Eqs. 3 and 4 sample all the fluctuations between particle deletion and nucleation that, on average, guide the overall morphology evolution of the system. However, many such fluctuations may cancel out, especially near equilibrium, leading to inefficient simulations where the overall morphology makes very little progress on average. In such scenarios it may be convenient to remove the fluctuations by considering net rates instead, defined as the difference between straight rates:

| (9) | ||||

| (10) |

These net rate equations are also implemented in MASKE, as a possible option for the mechanism. Their derivation is detailed in F. and are the activity products of the products of the dissolution and precipitation reactions, with and their equilibrium constants. The reactants of a dissolution reaction and the products of a precipitation reaction are solid phases, conventionally in standard state when stress-free, thus . G shows how the net rates in Eqs. 9 and 10 effectively scale linearly with the saturation index of the solution for the associated chemical reaction; namely, and , as usual in Transition State Theory. The definition of is:

| (11) |

noting that both the reactants of precipitation and the products of dissolution are simply the solvated species participating in the reaction. In a scenario where there is no excess enthalpy from changes in mechanical stress and interfacial energies, would imply equilibrium, i.e. no dissolution nor precipitation taking place, whereas would favour precipitation and dissolution.

2.3 Interaction potentials between identical particles

The energy from mechanical interactions plays an important role in the reaction rates in MASKE, via the excess enthalpy terms and in Eqs. 3 and 4, as implemented in the mechanism. All the examples in this article will employ a truncated harmonic potential of interaction between pairs of identical, spherical particles, and :

| (12) |

plotted in Fig. 4. is the interparticle distance. When the particles are at their equilibrium distance , the interaction energy is minimum and equal to the bond energy . The stiffness of the interaction is dictated by the parameter. The cutoff distance for the interaction, , is set here as the distance at which returns to zero when ; because of this definition, is not an independent parameter, but it is fixed once , , and are decided:

| (13) |

is obtained from the Young modulus of the material of the particles:

| (14) |

The particle diameter is close but not equal to , and their relationship depends on the modelling choice of the ‘limit crystal lattice’ of the solid phase. Depending on the type and range of the employed interaction potential, there are only several ordered arrangements, viz. crystal lattices, that are mechanically stable and where all the interacting particles sit at equilibrium distances. For instance, limit crystal lattices for the short-ranged, first-neighbour-only, radial interactions in Fig. 4, would be face centred cubic (FCC) or hexagonal close packing (HCP), both with first neighbours in the bulk. The mismatch between and emerges because any limit crystal lattice of spherical particles features a porosity and fills the space only up to a volume fraction . For example, both FCC and HPC lattices have packing fraction , hence a 26% porosity. However, if these limit lattices are used to discretise a non-porous continuum in a simulation, the maximum packing should represent a solid with same density as a non-porous phase, viz. with the same number of molecules, or mass, per unit volume. To exactly compensate for the artificial porosity , Coopamootoo and Masoero (2020) have proposed to use an smaller than by:

| (15) |

The expressions of excess enthalpy in Eqs. 3 and 4 () impose a dependence between interaction potential and solid-solution interfacial energy , which must be respected in order to produce physically meaningful simulations. Consider a particle in kink position in the crystal lattice, which by definition has first neighbours. Precipitating or dissolving a stress-free particle in a kink position should not change the excess enthalpy of the system, because it creates the same amount of solid-solution interfacial area as it removes. Such a dissolution (and similarly, in reverse, for precipitation) can be modelled, first, as a detachment of the kink particle from the solid, which causes a loss of inter-particle bonds each with energy (accounted for in the term), and second, as a dissolution of the detached particle which removes interfacial energy. This leads to:

| (16) |

2.4 Interaction potentials between different particles

One example in this article will feature mechanical interactions between particles of two different types, with different sizes and representing different materials. For such scenarios, Alex et al. (2023) have proposed an extension of the truncated harmonic potential in Fig. 4:

| (17) |

The equilibrium distance is the average of the equilibrium distances between identical particles for the two different types, 1 and 2. The stiffness term is expressed as , i.e. idealizing the interacting particles as two springs in series, with individual stiffness as per Eq. 14. The bond energy is , with the solid-solid interfacial energy between the particles and and their individual surface areas. Eq. 13 is still valid for the cutoff distance, using , , and in it.

2.5 Example 1: dissolution, growth, and equilibrium of a stress-free crystal

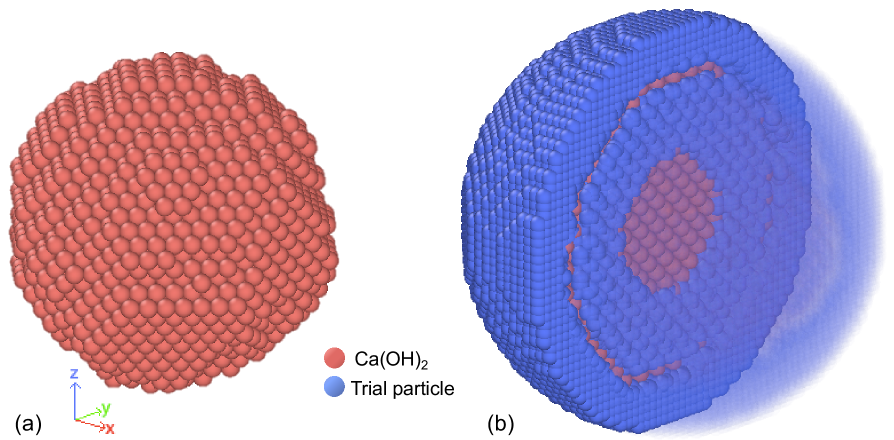

A nanocrystal of calcium hydroxide, Ca(OH)2, is considered in this example. The crystal is immersed in an aqueous solution of Ca2+ and OH- ions at room temperature K. The crystal is made of 4,055 spherical particles, each with the volume of one Ca(OH)2 molecule, nm3, where is the Avogadro number and cm3/mol is the molar volume of calcium hydroxide (indicated as in the subscript). This brings to a particle diameter nm. The particles are initially arranged on an FCC lattice with cell size , which implies that is the distance between first-neighbour particles in the lattice. Given the packing density of the FCC lattice, Eq. 15 provides nm.

The interaction potential between particles is the truncated harmonic one from Eq. 12. From the Young modulus GPa (Wittmann, 1986) of calcium hydroxide, Eq. 14 provides MPanm. The bond energy comes from Eq. 16, having considered an interfacial energy between calcium hydroxide and surrounding solution mJ/m2 (Estrela et al., 2005) and first neighbours for a bulk particle in the FCC lattice. The interaction cutoff distance thus becomes nm, from Eq. 13; this entails a failure strain , which is reasonable at the molecular scale. With these interactions, an initially cubic grain of FCC-arranged calcium hydroxide particles is pre-dissolved as in Masoero (2023b), obtaining the rounded grain with diameter of ca. 7.3 nm in Fig. 5, which is the configuration for this example.

A very large volume of solution is placed in contact with the solid grain, by setting nm3. In this way, particle dissolution and precipitation negligibly change the concentration of solvated ions, which retain their initially assigned values 111The apparent volumes of solvated Ca2+ and OH- ions, set to -0.025129603 nm3 and 0.001030404 nm3 respectively (Lothenbach et al., 2019) in the database, have a negligible effect in this example due to the large attached to the simulation box. The chemical reactions underlying dissolution and precipitation here are:

| (18) |

The value of is taken from Lothenbach et al. (2019). The solvated ions are assigned the following parameters to calculate their activities as well as the ionic strength of the solution: , nm, , and , nm, (Lothenbach et al., 2019). In this way, the activity product of the solvated ions for Eq. 18 can be computed for any initially imposed set of concentrations. The explored concentrations range from 0 for both Ca2+ and (saturation index ) to mmol/L, mmol/L (i.e. pH and ). Chemical equilibrium in stress-free conditions is expected at , which implies mmol/L and mmol/L (pH ) for the fixed ratio assumed here to ensure charge neutrality of the solution.

For the dissolution reaction in Eq. 18, the activation energy and standard state concentration of the activated complex are both computed from the rate constant of Ca(OH)2 dissolution in Bullard (2007): mol m-2 s-1. The conversion from mol m-2 to number of reactions per , which are the simulation units, yields nm-2. Eq. 5 then provides kJ/mol ag nm2 ns-2 in simulation units. For the precipitation reaction in Eq. 18, is assumed, thus kJ/mol ag nm2 ns-2. The activity coefficients of the activated complex are taken as , as usual for reactions involving solids (Domínguez et al., 1998).

Deletion of existing particles and nucleation of trial particles are sampled using two different subcommunicators: with 1 processor, and with 2 processors. For particle nucleation, a cubic lattice of 50,656 trial particles is employed, with lattice spacing in all three directions. The trial lattice is only created in a spherical shell region with inner and outer radii of 1.8 and 5 nm respectively, as shown in Fig. 5; this avoids the computational cost of sampling unlikely precipitation events far from the surface of the initial crystal, while leaving room for enough growth or dissolution to reach a steady state regime with constant average reaction rate. For the trial particles to move into a local minimum of interaction energy, 600 steps of energy minimisation are performed using the aforementioned algorithm, with time step of 0.45 ps and a maximum displacement per step of . Such a short minimization is appropriate because, for the interactions used here, a particle only needs to move by or less, to find its closest local energy minimum. The ions added/removed to/from the solution after particle dissolution/precipitation are distributed between the volume of solution in the simulation box and the additional in proportion to their volumes. However, since , changes in ion concentrations and saturation index saturation within the simulation box are negligible here. After each accepted dissolution or precipitation event, a process of type is invoked, which minimizes the total interaction energy by displacing all the real particles in the system; this is done via 10,000 steps of the LAMMPS algorithm, with timestep of 1 ps and a maximum displacement per step of 0.2 nm.

2.6 Example 2: strain-rate effect on a crystal under stress-driven dissolution

The nanocystal of Ca(OH)2 from the previous example is now brought into initial contact with two platens, via a procedure detailed in Masoero (2023b): see Fig. 6.a. The platens are arbitrarily discretized with particles of diameter in an FCC lattice, hence with equilibrium distance . The mechanical interactions between particles in the platens are of the form in Eq. 12, with elastic modulus typical of steel, GPa, which yields a high interaction stiffness, MPanm A high interfacial energy is then assumed between platen particles and the solution, mJ m, which leads to MPanm3. The resulting cutoff for the platen particles is nm, viz. a strain at failure of ca. 3.5%. The mechanical interactions between platen and Ca(OH)2 particles are of the form in Eq. 17, with equilibrium distance nm and interaction stiffness MPanm, obtained from the already computed, individual and stiffness of the two particle types. The platen-Ca(OH)2 bond energy is set to , making the interaction purely repulsive, i.e. and no bond under tension.

The volume of the simulation box is set to nm3, with an additional volume in contact with it nm3. The initial volume of the crystal is given by the initial number of Ca(OH)2 particles times their individual volume, nm3, hence the initial volume of solution (in plus in ) is nm3. The change in concentration of Ca2+ and OH- ions in solution caused by the dissolution of one Ca(OH)2 can be approximately estimated by neglecting the changes in solution volume caused by the reaction (MASKE accounts for them, through the volume of the Ca(OH)2 particle and the apparent volumes of solvated Ca2+ and OH- ions given in Section 2.5). For Ca2+, a dissolution event releases one molecule, hence changing approximately by mol/L; for OH- ions the change is mol/L. Therefore, in this example the dissolution of Ca(OH)2 particles during a simulation may significantly change the concentrations of ions in solution, and thus the saturation index .

Only the Ca(OH)2 particles are allowed to dissolve and to nucleate, via the same chemical reactions, thermodynamic and kinetic parameters, and trial precipitation lattice as in Example 1. The initial ion concentrations are set to mol/L and mol/L, implying . This means that no sustained dissolution nor precipitation is expected in stress-free conditions. All the particles in both platens are constrained not to move under the action of forces; this is done using the fix in LAMMPS. However, the particles in the top platen are rigidly displaced towards the bottom platen by 0.01 nm (via the command in LAMMPS) every nanoseconds of simulated time in MASKE. This is done by using a continuous process of type in the MASKE input script. The chosen value of controls the downward velocity of the top platen: nm/ns. The initial distance between the centres of mass of the two platens is 9.12 nm, hence the imposed strain rate is estimated in ns-1.

The platens put the Ca(OH)2 crystal under compression: see Fig. 6.b. The average compressive stress in the crystal, , is estimated as the per-particle virial stress in direction for each Ca(OH)2 particles, (computed in LAMMPS via a of type ), averaged over all the particles of Ca(OH)2 existing at any time in the simulation:

| (19) |

is the volume of the ith particle, j is the index of a neighbouring particle (of any type), is the number of neighbours mechanically interacting with particle , is the Z coordinate of the two interacting particles, and is the Z component of the force on each particle stemming from the pairwise interaction. The presence of per-particle stresses entails a nonzero excess enthalpy in the rate equations for dissolution and precipitation. As a result, the compression is expected to trigger dissolution of Ca(OH)2 even if the solution is initially at . As the compressive strain increases, dissolution will help relaxing the increasing , but the concurring increase in ion concentrations in solution, and thus of , will try to slow down dissolution and even cause precipitation of new Ca(OH)2 particles in stress-free regions of the crystal surface. All this will result in a complex kinetic balance between solution chemistry and mechanical stress, which will depend on the imposed strain rate and generate a non-trivial evolution of the crystal morphology through dissolution/precipitation events and plastic deformations.

3 Results

3.1 Example 1: dissolution, growth, and equilibrium of a stress-free crystal

This section considers the Ca(OH)2 nanocrystal described in Section 2.5, with the aim of assessing: (1) whether the simulations correctly predict the transition from crystal dissolution to growth that, for stress-free crystals, is expected as the solution goes from undersaturated () to supersaturated (); (2) the variability in the results stemming from the random numbers involved in the Kinetic Monte Carlo algorithm (see B to appreciate the role of random numbers); (3) how the fineness of the lattice of trial particles may impact the results; (4) the pros and cons of using straight or net rates (viz. Eqs. 3 and 4 rather than Eqs. 9 and 10).

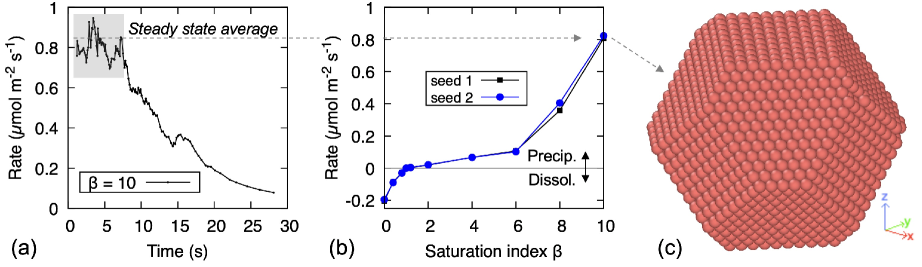

Fig. 7 shows precipitation and dissolution rates obtained from simulations using net rates. The rates are expressed per unit area of crystal surface and per unit time. To estimate , knowing the volume of a Ca(OH)2 particle and the number of particles at any give time in a simulation, one can compute the total volume of the crystal , and set , having approximated the whole crystal as a sphere. Fig. 7.a shows a typical curve of precipitation rate (averaged over the 100 KMC events before the current one) vs. simulated time. The time scale extends to various seconds, despite the nanometre scale of the system: this ability to sample long time scales irrespective of the length scale being considered, is a strength of the KMC approach. Fig. 7.a also shows a steady state of constant rate in the initial part of the simulation; this happens for all and values, but not when . The steady state values are plotted against in Fig. 7.b; for the range, the plotted rate is the one averaged over the first 100 KMC steps of a simulation. Fig. 7.b shows that: (i) dissolution (viz. a negative precipitation rate) is correctly predicted when , as well as precipitation when and and chemical equilibrium (viz. zero rate) when . The figure also shows that the sequence of pseudo-random numbers used in the KMC algorithm has a negligible effect on the average rates (‘seed 1’ and ‘seed 2’ indicate two difference sequences).

Transition State Theory (TST) predicts a linear relationship between rates per unit surface and ; by contrast the simulations, despite using rates that are based on TST, produce a nonlinearity in the range: see Fig. 7.b. This effect is due to the crystal morphology. An overall linear relationship, as per TST, requires that kink sites are not exhausted during precipitation; this is possible if there is a very large number of such sites in the initial crystal, which is not the case for the nanocrystal simulated here. Alternatively, new kink sites must be created rapidly, which is possible if is large compared to the energy barriers of precipitating particles with fewer neighbours than a kink site, , or if rare, energetically unfavourable fluctuations favour precipitation in under-coordinated sites, such as adatoms, which provide starting points for the growth of new layers. The latter scenario is impossible when net rates are used, as they average out all the energetically unfavourable fluctuations. As a result in Fig. 7.b, when , precipitation is short-lived as it only consumes the initial kink sites. The continuous exhaustion of kink sites causes a continuous decrease in rate, which explains why a steady state is not established in said range. When , instead, new kink sites can be formed on certain crystal facets and precipitation can proceed further and faster. However, when the layers growing from facets on which new kinks can form at are exhausted, precipitation stops and the crystal ends up with the clear-cut morphology in Fig. 7.c. Even higher values would enable formation of new kinks on other facets too, thus sustaining further precipitation; a systematic exploration of these thresholds is not of primary interest here, but an indication of this process at play will be given later in Example 2. A close inspection of Fig. 7.b reveals a nonlinear increase in dissolution rate also as approaches 0. This happens because a very low enables the dissolution of sites that are more coordinated than kinks, creating vacancies (or ‘pits’) on the crystal surfaces where new dissolution fronts can emanate, accelerating the overall process.

The effect of energetically unfavourable fluctuations is shown in Fig. 8.a,b, with simulation results from using straight rates. The parameter in the rate equations controls how prevalent the effects of fluctuations are. The explored values are (as usual in Transition State Theory), which attributes all the excess enthalpy from mechanical interactions to the dissolution reaction only and maximizes the fluctuations, to , which equally distributes the excess enthalpy between dissolution and precipitation, minimizing fluctuations but not removing them (as opposed to net rates). Fig. 8.a shows that all the results from straight rates predict a linear relationship between overall rate and , also in the range where net rates were unable to nucleate new crystal layers. Straight rates instead always enable the formation and stabilization of adatoms (e.g. those circled in Fig. 8.b) which allow for indefinite growth. A close inspection of Fig. 8.a reveals a slight shift of equilibrium (i.e. rate = 0) towards values that are slightly greater than 1; this is the effect of relying on an estimated value of when explicitly sampling both dissolution and precipitation events (here was set to ).

All the simulations with straight rates, , and produce the same morphology as in Fig. 8.b, which is reached when the entire nucleation lattice is covered by real particles; further growth is expected if bigger lattices were used. The same morphology is expected to emerge when and , but in this case the simulations were stopped after a few thousands atoms precipitated, because of the high computational cost of sampling many unlikely fluctuations. Indeed, the precipitation of ca. 500 particles at required ca. 10,000 KMC steps in simulations with and 8,000 steps when , as opposed to 800 steps with , and 500 steps for net rates. On the other hand, Fig. 8.a shows that the precipitation rates compute with are significantly underestimated in all the other simulations with , as well as when net rates are used. This confirms that rare fluctuations are important for quantitatively capturing the nucleation of new layers. Therefore, when using MASKE one should judge on a case-by-case basis whether to use straight or net rates and, in case, which value of , in order to balance the requirements of running rapid calculations, predicting qualitatively correct mechanisms, and obtaining quantitatively correct rates.

A last parametric study here concerns the impact of the fineness of the nucleation lattice on the resulting average rates. For simulations using net rates, Fig. 8.c shows the temporal increase in at when cubic nucleation lattices of different spacing are employed. All simulations with lattice spacing less than , viz. with , return very similar results 222The simulation with was stopped earlier because it entailed the sampling of ca. 1.4 million trial particles, as opposed to ca. 50,000 when and ca. 6,000 when . Coarser lattices however, with , underestimate precipitation because they miss energetically convenient minima in the interaction energy landscape. This indicates that a nucleation lattice spacing of or less is appropriate for the simulations and the mechanical interaction potentials considered here.

3.2 Example 2: strain-rate effect on a crystal under stress-driven dissolution

In this example, the Ca(OH)2 crystal from the previous section is surrounded by a relatively small volume of solution, which is initially at chemical equilibrium with the crystal itself, viz. . The crystal is then subjected to a compressive strain with fixed rate, which should favour the dissolution of particles under high mechanical stress. The dissolving particles increase the concentration of Ca2+ and OH- in solution, hence its saturation index too; this may cause precipitation of new Ca(OH)2 particles in regions of the crystal surface that are under low mechanical stress. At high imposed strain rates, plastic deformations may occur too.

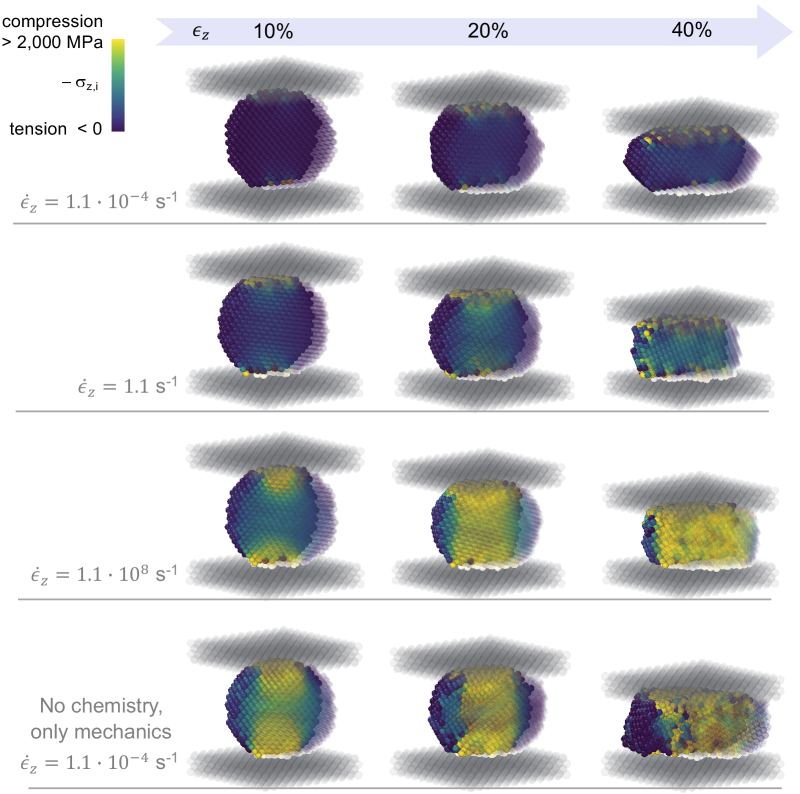

Fig. 9 shows the deformation and stress field of the Ca(OH)2 crystal when compressed at different strain rates . The KMC algorithm in MASKE allows exploring a broad range of strain rates, here from s-1 to s-1; this is valuable because the experiments typically impose rates in the order of the lowest values here, which are difficult to reach with other simulation techniques (e.g. molecular dynamics; Cao et al. (2019)). All the simulations in Fig. 9 employed net rates; some considerations on the effect of straight rates will be made later in this section.

At low strain rates, s-1 in Fig. 9, the dissolution triggered by the per-particle stress (via the excess enthalpy in the rate equations) is fast compared to the deformation process. As a result, the dissipation of local stress through dissolution is efficient, therefore the local stress remains relatively low even at high , as shown by the dark violet color in the % snapshot in Fig. 9. The same snapshot shows significant recrystallization, driven by the increase of in solution eventually triggering precipitation of new Ca(OH)2 in low-stress regions.

Higher strain rates induce higher per-particle stresses : see and s-1 in Fig. 9. For compatibility of displacements, the rate at which a layer of particles in contact with the platens dissolves must equal the velocity at which the top platen moves. A higher strain rate entails a higher platen velocity, which requires a higher dissolution rate, achieved by allowing a slightly higher strain before dissolution, which in turn increases the local stress and thus the excess enthalpy term in the rate. Fig. 9 also shows that little recrystallization takes place at high strain rates. This is because the precipitation rate scales linearly with , and therefore with the number of dissolved particles (assuming that no reprecipitation takes places at all, which is a good approximation at high strain rates). At a given strain level , the number of dissolved particles is basically the same irrespective of the imposed strain rate (for sufficiently high ). By contrast, the strain rates have been increased by orders of magnitude here, as well as the dissolution rates required to accommodate the strain; in the resulting short timescales of the deformation/dissolution processes, precipitation events become rare. In the simulation with highest strain rate, s-1, the animation of the full chemo-mechanical process in Fig. 9 shows that plastic shear slips along crystalline planes occur at high strain levels, . Such slips are not recorded at lower strain rates, where the dissolution-induced relaxation of local stresses prevents the activation of plastic deformations.

Fig. 9 also shows results for a purely mechanical response, i.e. with both dissolution and precipitation turned off. The simulation was conducted at a low strain rate s-1, but the same result would be obtained at higher strain rates because the particles are brought to static equilibrium between two successive execution of the platen-moving continuous process in MASKE (static equilibrium is imposed via a MASKE process of type performing energy minimization in MASKE). Therefore inertial effects do not contribute to rate-dependence here. The purely mechanical response in Fig. 9 is somewhat similar to the coupled chemo-mechanical one at high s-1, but with some important differences too. At low strain levels (see in Fig. 9), even the limited dissolution taking place at s-1 is sufficient to reduce the local stresses compared to the purely mechanical test. At and the purely mechanical test displays a wider low-stress region near the surface of the crystal; the particles in this region do not contribute significantly to the overall mechanical response to the compression. Partial dissolution at instead moulds the crystal layers in contact with the platens, removing particles with high that induce stress concentration, and thus enabling a more uniform mechanical response. Another distinctive aspect of the purely mechanical test is that extensive plastic deformations from shear slips already start at , and a fully developed central shear band controls the entire deformation response at . In the dissolving crystal with , instead, small and isolated, plastic shear slips only start appearing at .

Fig. 10.a shows the stress strain curves computed at different strain rates . A higher produces a higher average compressive stress ; this reflects the already-discussed need for faster dissolution (whose rate depends on local stresses) to ensure compatibility of displacements at the platen-crystal interface.

A counter-intuitive result in Fig. 10.a is that crystals that are allowed to dissolve, when compressed at high rates, are stronger than crystals that are not allowed dissolve. This is indicated in Fig. 10.a, by the higher peak of the curve for s-1, compared to the ‘mech. only’ curve. The ‘mech. only’ curve lacks the mechanism of particle dissolution, which helps relaxing the local stresses on particles while ensuring compatibility of displacement at the crystal-platen interface. Such compatibility, in the ‘mech. only’ simulation, relies entirely on mechanical deformations; these are initially elastic and, when local stresses become too high, plastic shear slips are triggered and relax the local stress. One may thus expect that the ‘mech. only’ simulation, being more constrained, would produce a higher than simulations where dissolution is possible too. This is indeed the case at low strain levels: see in Fig. 10.a. However, the first extensive shear slips in the ‘mech. only’ simulation occur already at . After that point, subsequent shear slips effectively cap the peak stress to ca. 2’000 MPa. By contrast, in the s-1 simulation, dissolution of the most stressed particles limits the maximum local stress, which gets redistributed as a lower stress to the particles neighbouring the dissolved one. All this leads to a more uniform stress distribution in the crystal (see Fig. 9) while also delaying the triggering of plastic slips until . As a result, the peak stress in the s-1 is ca. 2’500 MPa, greater than in the ‘mech. only’ case.

Another finding from Fig. 10.a is the stepwise stress-strain curve at the lowest strain rate, s-1. Specifically, increases with for a while, then it oscillates around a constant value while keeps increasing, until a new regime of increasing is entered, and so forth. Three such steps can be counted in Fig. 10.a. This behaviour is the result of the kinetic chemo-mechanical balance established during the simulations. At low rates , no plastic deformations are triggered and particle dissolution is the only mechanisms to accommodate the externally imposed . When compression starts, the first dissolution events release ions in solution, raising the saturation index for Ca(OH)2 precipitation: see the increasing at in the s-1 curve in Fig. 10.b. With the net rate equations used here, Example 1 in the previous section has shown that no significant precipitation is possible when , hence keeps increasing. The increasing slows down dissolution but, since the overall rate is imposed and must be matched, a compensating increase in dissolution rate is made possible through an increase in mechanical stress (which increases the excess enthalpy term in the dissolution rate equation). This explains the regimes of increasing in Fig. 10.a, which indeed correspond to regimes of increasing in Fig. 10.b. At , particle precipitation consumes any further ion that dissolution releases in solution, so that the average rate (precipitation minus dissolution over 100 KMC steps) oscillates around zero: see the curve for s-1 in Fig. 10.c when . As a result, now remains constant while increases, and the constant overall rate implies that the stress must remain constant too. This explains the matching plateaus in Figs. 10.a and 10.b. The first plateau continues until exhausting all the surface sites where precipitation at is possible: cf. the final morphology in Fig. 7.b. Then a new regime of increasing and is entered, until a new plateau occurs at , when precipitation on other exposed crystal surfaces becomes possible too. The new plateau again corresponds to a net dissolution rate oscillating around zero, in Fig. 10.c. All this describes a complex, kinetic equilibrium between composition of the solution, stress state in the crystal, and microstructural evolution.

The stepwise shape of the stress-strain curve is lost at higher strain rates, as shown by the s-1 curves in Fig. 10. Additional results omitted here show a progressive reduction and disappearance of the plateaus for intermediate rate values between s-1 and 1 s-1. This means that, despite some particles do still precipitate when , they cannot compete any more with the faster rate of the dissolving particles. Consistently, when s-1 the saturation index increases monotonically in Fig. 10.b and the average dissolution rate never goes to zero in Fig. 10.c. The curves in Fig. 10.b for and s-1 are similar, meaning that dissolution progresses at a similar rate. This is expected because, in a scenario where precipitation is negligible, the total amount of dissolved ions depends only on the accommodated strain . If is approximately identical for and s-1, then is necessarily greater at the higher imposed rate, since only now can speed up the dissolution rate to match . Less intuitively, the curve for s-1 in Fig. 10.b is initially similar to those for and s-1, but it significantly diverges from them at , leading to less concentrated solutions at high strain levels . The reason for this lies in the triggering of plastic deformations at high rate, s-1, which cap the stress level (see at in Fig. 10.a) and provide another mechanism to accommodate the imposed strain. With a capped , the increasing reduces the dissolution rate, which in turn reduces the slope of the curve in Fig. 10.b. The resulting interdependence between plastic deformations and composition of the solution is another non-trivial result of the chemo-mechanical coupling in MASKE.

All the results in this section are from simulations where the mechanism in MASKE employed net rates of dissolution and precipitation, as per Eqs. 9 and 10. Additional tests were conducted using straight rates too, as per Eqs. 3 and 4, with values between 0 and 0.5. At high strain strain rates, s-1, straight and net rates produce almost identical results; this is expected, since the main effect of using straight straight is to favour precipitation, which plays a negligible role at high . Instead, at low , simulations using straight rates produced lower than those from net rates at same . This agrees with the findings from Example 1 in the previous section, where straight rates were shown to enable precipitation at lower values. Therefore, simulations with straight rates are indeed expected to produce plateaus in and at lower than simulations with net rates. These aspect, however, should be studied further because the efficiency loss from using straight rates significantly limited the maximum that could be reached during the simulations. For the purpose of this paper, the results presented here for net rates have already demonstrated how MASKE can predict the emergence of a complex kinetic balance between chemical and mechanical processes over long time scales.

4 Conclusion and outlook

The article has introduced MASKE, a kinetic simulator of microstructural evolution driven by chemical reactions and mechanical stress. Solid domains are modelled as mechanically interacting particles, while the surrounding environment, which was an aqueous solution in the examples here, is modelled implicitly through the concentrations of molecular species in it. The composition of the solution co-evolves with the solid phases, in respect of mass conservation, all while dissolution and precipitation reactions transform molecules from the solid into solvated species and vice versa.

The uniqueness of MASKE stems from several key strengths:

-

1.

MASKE implements an off-lattice, rejection-free, Kinetic Monte Carlo (KMC) framework to simulate the dissolution and precipitation of particles. This framework gives access to realistic time scales that are relevant for the experiments;

-

2.

MASKE features original chemo-mechanical rate equations for dissolution and precipitation, which capture the effect of mechanical stress on the reaction rates. To simulate the deformations that induce mechanical stress, the particles are free to move off-lattice, but this implies that infinite positions are to be sampled for possible particle precipitation. To treat this issue, a discretization method has been proposed which approximates the integral of the precipitation rate over the whole simulation box by considering only a finite number of trial particles;

-

3.

The reaction rates are implemented in both straight and net forms. Depending on the application, the user can opt for the computational efficiency of net rates, or for more computationally demanding but also more precise (mechanistically and quantitatively) simulations using straight rates;

-

4.

The KMC sampling of discrete dissolution/precipitation events is coupled with the explicit integration of continuous processes. In the article, this coupling has been exploited to impose a strain rate. Other continuous processes are currently being implemented, in particular one that simulates the metabolic activity of bacteria, explicitly modelled as particles as in Li et al. (2019), for the purpose of modelling biomineralization in self-healing concrete Bagga et al. (2022);

-

5.

In MASKE, the user can define bespoke chemical reactions and mechanisms in a chemistry database file. MASKE is also interfaced with the LAMMPS library, through which the user can specify complex initial microstructures, loading conditions, and interaction potentials. As a result, a wide variety of problems with disparate chemistries can be simulated;

-

6.

MASKE features a two level parallelisation, ready for use in High Performance Computing. The simulations in this article used both levels of parallelisation, but on simple examples that required only 3 processors in total (despite one simulation already featured 1.4 million trial particles). Applications of MASKE involving more processors have been presented elsewhere (Coopamootoo and Masoero, 2020; Alex et al., 2023).

A number of additional features provide promising avenues for further development. These in particular may involve:

-

1.

Coarse-graining the reaction rates to reach microstructural scales. The mechanism presented here is only accurate for unimolecular reactions, but Shvab et al. (2017) already proposed coarse-grained rate expression for nanoparticles with diameter of ca. 10 nm. The version of MASKE that is currently on GitHub already includes a mechanism for particles with diameter of m, which will be presented in a separate article;

-

2.

Allowing particles to partially grow or dissolve, whereas now they can only appear or disappear at once. This would be desirable when using coarser particles, to avoid unrealistically large, sudden changes in stress (and thus in stress-dependent reaction rates) when a full particle is deleted or added. Partial dissolution and growth would thus be important for capturing well certain phenomena, such as crystallization pressure (Masoero, 2023b). Even better if the partial growth or dissolution of particles were anisotropic. Such anisotropy would at least require ellipsoidal particles, which would be rather straightforward to include in MASKE, since ellipsoidal particles and appropriate potentials for them already exist in LAMMPS (Berardi et al., 1998). However, partial growth and dissolution (either as discrete KMC events or as continuous processes) will require additional implementation and a new, probably less efficient, way of sampling energy changes to compute the excess enthalpy terms in the reaction rates;

-

3.

Improving the model of the solution, allowing for heterogenous local concentrations of solvated molecules, which may also react chemically within the implicit fluid. For the reactions in solution, there is ongoing work to couple MASKE with the PHREEQC library (Parkhurst et al., 1999). Heterogeneous concentrations would be desirable for simulations at larger length scales, and the resulting concentration gradients would prompt diffusion that can be implemented in MASKE as a continuous process to be integrated in time.

Two examples in this article have shown that MASKE, already in its current form, can capture interesting coupled phenomena that challenge other simulation methods. Example 1 confirmed that MASKE correctly predicts the dissolution, growthm and chemical equilibrium of a nanocrystal of Ca(OH)2, depending on the concentrations of Ca2+ and OH- ions in the surrounding solution. Straight rate equations have been shown to effectively allow the nucleation of new crystal layers through energetically unfavourable fluctuations. Example 2 then addressed the effects of chemo-mechanical coupling, by imposing a compressive strain rate to the crystal. The results showed that a complex kinetic balance is established between dissolution rates, chemical composition of the solution surrounding the crystal, elastic stress state in the crystal, and plastic deformations too. A family of curves is obtained, which quantifies the stress-strain response of the crystal as a function of the imposed strain rate. These curves offer a constitutive models for simulations al larger scales, e.g. continuum simulations based on the Finite Element Method. All in all, MASKE offers a new way to reconstruct the chemo-mechanical kinetics of evolving microstructures. This capability can be leveraged to simulate the formation and behaviour of new materials in computer-aided design, and to predict the degradation of materials for both conventional and accidental scenarios of future exposure.

References

- Alex et al. (2023) Alex, A., Freeman, B., Jefferson, A., Masoero, E., 2023. Carbonation and self-healing in concrete: Kinetic monte carlo simulations of mineralization. Cement and Concrete Composites , 105281.

- Bagga et al. (2022) Bagga, M., Hamley-Bennett, C., Alex, A., Freeman, B.L., Justo-Reinoso, I., Mihai, I.C., Gebhard, S., Paine, K., Jefferson, A.D., Masoero, E., et al., 2022. Advancements in bacteria based self-healing concrete and the promise of modelling. Construction and Building Materials 358, 129412.

- Bažant et al. (1997) Bažant, Z.P., Hauggaard, A.B., Baweja, S., Ulm, F.J., 1997. Microprestress-solidification theory for concrete creep. I: Aging and drying effects. Journal of Engineering Mechanics 123, 1188–1194.

- Bellomo et al. (2012) Bellomo, F.J., Armero, F., Nallim, L.G., Oller, S., 2012. A constitutive model for tissue adaptation: necrosis and stress driven growth. Mechanics Research Communications 42, 51–59.

- Bentz et al. (1994) Bentz, D.P., Coveney, P.V., Garboczi, E.J., Kleyn, M.F., Stutzman, P.E., 1994. Cellular automaton simulations of cement hydration and microstructure development. Modelling and Simulation in Materials Science and Engineering 2, 783.

- Berardi et al. (1998) Berardi, R., Fava, C., Zannoni, C., 1998. A gay–berne potential for dissimilar biaxial particles. Chemical physics letters 297, 8–14.

- Bishnoi and Scrivener (2009) Bishnoi, S., Scrivener, K.L., 2009. ic: A new platform for modelling the hydration of cements. Cement and Concrete Research 39, 266–274.

- Bullard (2007) Bullard, J.W., 2007. A three-dimensional microstructural model of reactions and transport in aqueous mineral systems. Modelling and Simulation in Materials Science and Engineering 15, 711.

- Bullard et al. (2010) Bullard, J.W., Enjolras, E., George, W.L., Satterfield, S.G., Terrill, J.E., 2010. A parallel reaction-transport model applied to cement hydration and microstructure development. Modelling and Simulation in Materials Science and Engineering 18, 025007.

- Bullard et al. (2011) Bullard, J.W., Lothenbach, B., Stutzman, P.E., Snyder, K.A., 2011. Coupling thermodynamics and digital image models to simulate hydration and microstructure development of portland cement pastes. Journal of Materials Research 26, 609–622.

- Cao et al. (2019) Cao, P., Short, M.P., Yip, S., 2019. Potential energy landscape activations governing plastic flows in glass rheology. Proceedings of the National Academy of Sciences 116, 18790–18797.

- Cefis and Comi (2017) Cefis, N., Comi, C., 2017. Chemo-mechanical modelling of the external sulfate attack in concrete. Cement and Concrete Research 93, 57–70.

- Coopamootoo and Masoero (2020) Coopamootoo, K., Masoero, E., 2020. Simulations of crystal dissolution using interacting particles: prediction of stress evolution and rates at defects and application to tricalcium silicate. The Journal of Physical Chemistry C 124, 19603–19615.

- Coopamootoo K (2023) Coopamootoo K, M.E., 2023. Simulations of tricalcium silicate dissolution at screw dislocations: effects of fnite crystal size and mechanical interaction potentials. Cement and Concrete Research In press.

- Domínguez et al. (1998) Domínguez, A., Jimenez, R., López-Cornejo, P., Pérez, P., Sánchez, F., 1998. On the calculation of transition state activity coefficient and solvent effects on chemical reactions. Collection of Czechoslovak chemical communications 63, 1969–1976.

- Dubrovskii et al. (2010) Dubrovskii, V., Sibirev, N., Zhang, X., Suris, R., 2010. Stress-driven nucleation of three-dimensional crystal islands: from quantum dots to nanoneedles. Crystal growth & design 10, 3949–3955.

- Estrela et al. (2005) Estrela, C., Estrela, C.R.d.A., Guimarães, L.F., Silva, R.S., Pécora, J.D., 2005. Surface tension of calcium hydroxide associated with different substances. Journal of Applied Oral Science 13, 152–156.

- Feng et al. (2017) Feng, P., Bullard, J.W., Garboczi, E.J., Miao, C., 2017. A multiscale microstructure model of cement paste sulfate attack by crystallization pressure. Modelling and simulation in materials science and engineering 25, 065013.

- Freeman et al. (2019) Freeman, B.L., Cleall, P.J., Jefferson, A.D., 2019. An indicator-based problem reduction scheme for coupled reactive transport models. International Journal for Numerical Methods in Engineering 120, 1428–1455.

- Gawin et al. (2009) Gawin, D., Pesavento, F., Schrefler, B.A., 2009. Modeling deterioration of cementitious materials exposed to calcium leaching in non-isothermal conditions. Computer Methods in Applied Mechanics and Engineering 198, 3051–3083.

- Hart et al. (2017) Hart, N.H., Nimphius, S., Rantalainen, T., Ireland, A., Siafarikas, A., Newton, R., 2017. Mechanical basis of bone strength: influence of bone material, bone structure and muscle action. Journal of musculoskeletal & neuronal interactions 17, 114.

- Ioannidou et al. (2016) Ioannidou, K., Krakowiak, K.J., Bauchy, M., Hoover, C.G., Masoero, E., Yip, S., Ulm, F.J., Levitz, P., Pellenq, R.J.M., Del Gado, E., 2016. Mesoscale texture of cement hydrates. Proceedings of the National Academy of Sciences 113, 2029–2034.

- Ioannidou et al. (2022) Ioannidou, K., Labbez, C., Masoero, E., 2022. A review of coarse grained and mesoscale simulations of c–s–h. Cement and Concrete Research 159, 106857.

- Ioannidou et al. (2014) Ioannidou, K., Pellenq, R.J.M., Del Gado, E., 2014. Controlling local packing and growth in calcium–silicate–hydrate gels. Soft Matter , 1121–1133.

- Kouhen et al. (2023) Kouhen, M., Dimitrova, A., Scippa, G.S., Trupiano, D., 2023. The course of mechanical stress: Types, perception, and plant response. Biology 12, 217.

- Langmuir (1997) Langmuir, D., 1997. Aqueous environmental. Geochemistry Prentice Hall: Upper Saddle River, NJ 600.

- Lasaga (2014) Lasaga, A.C., 2014. Kinetic theory in the earth sciences. Princeton University Press.

- Li et al. (2019) Li, B., Taniguchi, D., Gedara, J.P., Gogulancea, V., Gonzalez-Cabaleiro, R., Chen, J., McGough, A.S., Ofiteru, I.D., Curtis, T.P., Zuliani, P., 2019. Nufeb: A massively parallel simulator for individual-based modelling of microbial communities. PLoS Computational Biology 15, e1007125.

- Li et al. (2015) Li, X., Grasley, Z., Garboczi, E.J., Bullard, J.W., 2015. Modeling the apparent and intrinsic viscoelastic relaxation of hydrating cement paste. Cement and Concrete Composites 55, 322–330.

- Lothenbach et al. (2019) Lothenbach, B., Kulik, D.A., Matschei, T., Balonis, M., Baquerizo, L., Dilnesa, B., Miron, G.D., Myers, R.J., 2019. Cemdata18: A chemical thermodynamic database for hydrated portland cements and alkali-activated materials. Cement and Concrete Research 115, 472–506.

- Martin et al. (2020) Martin, P., Gaitero, J.J., Dolado, J.S., Manzano, H., 2020. Kimera: a kinetic montecarlo code for mineral dissolution. Minerals 10, 825.

- Masoero (2023a) Masoero, E., 2023a. MASKE GitHub Repository.

- Masoero (2023b) Masoero, E., 2023b. Maske: Particle-based chemo-mechanical simulations of degradation processes, in: International RILEM Conference on Synergising expertise towards sustainability and robustness of CBMs and concrete structures, Springer. pp. 159–170.

- Meakin and Rosso (2008) Meakin, P., Rosso, K.M., 2008. Simple kinetic monte carlo models for dissolution pitting induced by crystal defects. The Journal of chemical physics 129.

- Parkhurst (1995) Parkhurst, D.L., 1995. User’s guide to PHREEQC: A computer program for speciation, reaction-path, advective-transport, and inverse geochemical calculations. 95-4227, US Department of the Interior, US Geological Survey.

- Parkhurst et al. (1999) Parkhurst, D.L., Appelo, C., et al., 1999. User’s guide to phreeqc (version 2): A computer program for speciation, batch-reaction, one-dimensional transport, and inverse geochemical calculations. Water-resources investigations report 99, 312.

- Parrott (1975) Parrott, L., 1975. Increase in creep of hardened cement paste due to carbonation under load. Magazine of Concrete Research 27, 179–181.

- Pesavento et al. (2012) Pesavento, F., Gawin, D., Wyrzykowski, M., Schrefler, B.A., Simoni, L., 2012. Modeling alkali–silica reaction in non-isothermal, partially saturated cement based materials. Computer Methods in Applied Mechanics and Engineering 225, 95–115.

- Prados et al. (1997) Prados, A., Brey, J., Sánchez-Rey, B., 1997. A dynamical monte carlo algorithm for master equations with time-dependent transition rates. Journal of statistical physics 89, 709–734.

- Raja and Shoji (2011) Raja, V., Shoji, T., 2011. Stress corrosion cracking: theory and practice. Elsevier.

- Rutter (1983) Rutter, E., 1983. Pressure solution in nature, theory and experiment. Journal of the Geological Society 140, 725–740.

- Scherer (2004) Scherer, G.W., 2004. Stress from crystallization of salt. Cement and concrete research 34, 1613–1624.

- Shvab et al. (2017) Shvab, I., Brochard, L., Manzano, H., Masoero, E., 2017. Precipitation mechanisms of mesoporous nanoparticle aggregates: off-lattice, coarse-grained, kinetic simulations. Crystal Growth & Design 17, 1316–1327.

- Thompson et al. (2022) Thompson, A.P., Aktulga, H.M., Berger, R., Bolintineanu, D.S., Brown, W.M., Crozier, P.S., in’t Veld, P.J., Kohlmeyer, A., Moore, S.G., Nguyen, T.D., et al., 2022. Lammps-a flexible simulation tool for particle-based materials modeling at the atomic, meso, and continuum scales. Computer Physics Communications 271, 108171.

- Tourret et al. (2022) Tourret, D., Liu, H., LLorca, J., 2022. Phase-field modeling of microstructure evolution: Recent applications, perspectives and challenges. Progress in Materials Science 123, 100810.

- Truesdell and Jones (1974) Truesdell, A.H., Jones, B.F., 1974. Wateq, a computer program for calculating chemical equilibria of natural waters. J. Res. US Geol. Surv 2, 233–248.